EDI 856 format

The EDI 856 is a report used to communicate what’s in a shipment and how it’s packed. This report is made up of different parts that each provide various details about the shipment. Imagine the EDI 856 as a very detailed packing list that helps each company know exactly what’s being shipped and how.

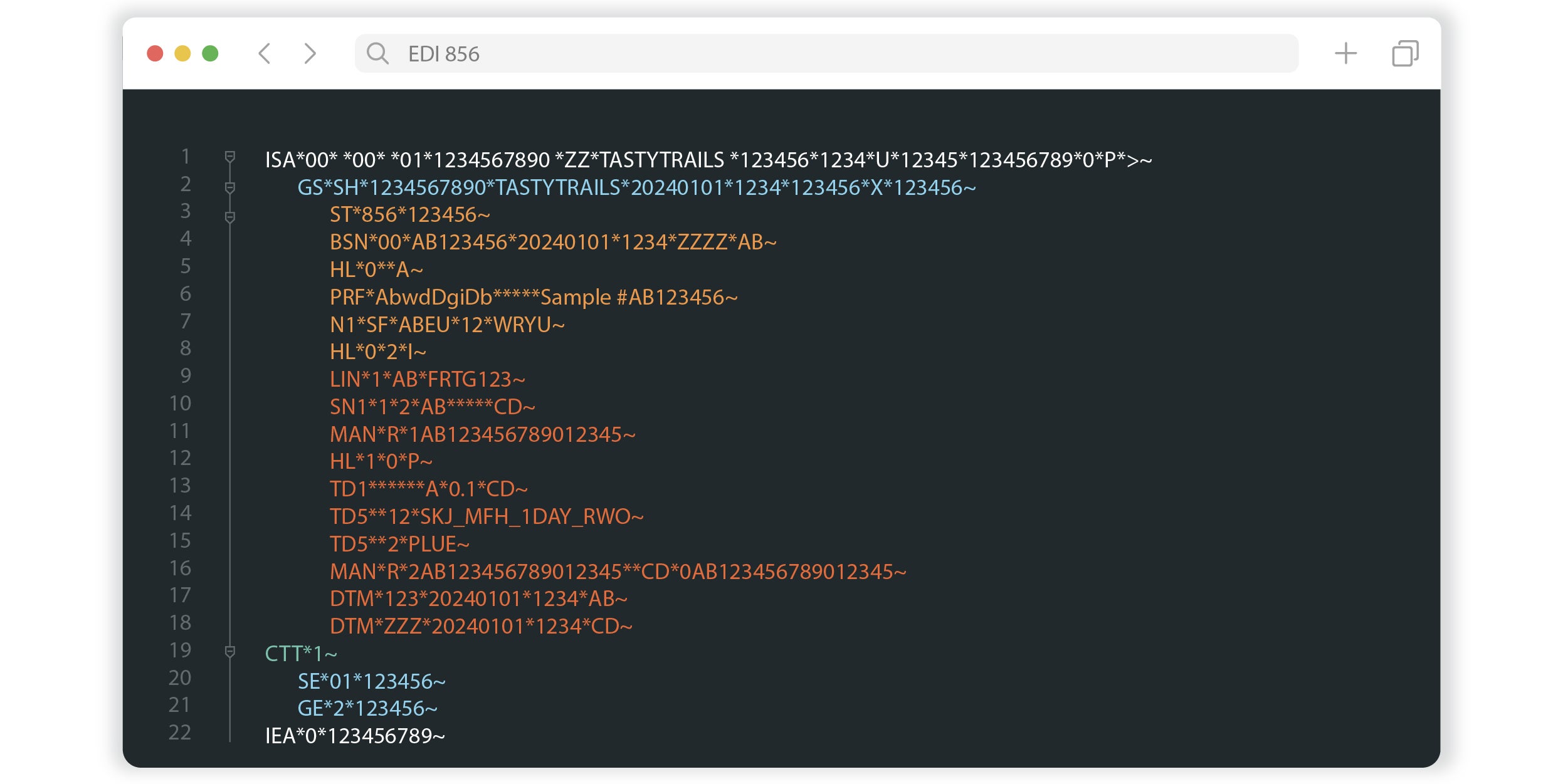

The EDI 856 is made up of many pieces:

How is EDI 856 used?

The EDI 856 is a tool for keeping track of products that are shipped from one location to another. It’s like a cheat sheet that tells you what’s inside each box, how many there are, and how they’re all packed together.

Shipment details

Order fulfillment

Inventory management

Efficient receiving

Tracking

Discrepancy resolution

Automated processing

Does the ASN change per fulfillment model?

The ASN doesn’t really change. Whether your company ships via cross-docking, direct-to-store, or drop shipping, the ASN stays the same but helps in different ways.

Let’s see how makes different fulfillment models more efficient:

Direct-to-store or warehouse delivery

Drop shipping

Cross-docking or distribution center

Benefits of using the EDI 856 Advance Ship Notice

All trading partners providers benefit from implementing the Advance Ship Notice. To optimize benefits, the document should be sent at the time of the physical shipment.

Retailer and distributor benefits:

Cut costs of receiving goods

Reduce the need for safety stock

Improve speed and accuracy of receiving goods

Facilitate better labor and equipment scheduling

Gain visibility into inbound shipments and make adjustments to plans to accommodate incomplete or late shipments

Supplier benefits:

Reduce order to payment cycles

Get products on store shelves faster

More easily track shipments en route

Track any missing cartons and make claims accordingly

Improve retailer relationships by reducing stock outs, errors and missed deliveries

Common issues regarding EDI 856

Barcode labels:

Issues with barcode labels, such as discrepancies between the barcode and the ASN, can occur. This often results in requiring the receiver to manually sort packages, leading to increased labor costs and potential chargebacks or penalties for suppliers.

Completeness and accuracy:

If ASN data isn’t accurate or complete, there will be delays, lost productivity and customer service shortfalls. Validating the completeness and accuracy of the ASN data is important to avoid confusion and subsequent penalties and fines.

Timeliness:

Trading partners typically require an ASN to arrive prior to the shipment. Understanding each trading partner’s requirements for ASN delivery will help prevent chargebacks.

Automate 856 Advance Ship Notice with Full-Service EDI from SPS Commerce

Managing ongoing EDI tasks can be complex and time-consuming. Full-service EDI providers like SPS Commerce deliver EDI technology and associated staffing resources responsible for customizing, optimizing and operating your EDI solution.

SPS communicates directly with your trading partners to manage connectivity, setup, requirements, updates and support efforts. SPS also takes ownership of understanding your trading partner requirements and making map changes.

SPS Fulfillment proactively monitors and optimizes your solution to prevent errors and minimize data entry.

Interested in learning more about our EDI solution?

Additional EDI Resources

Enter a virtual library of information about EDI for suppliers, vendors and distributors to provide you with the product knowledge you need to power your business.

Ultimate List of EDI Transactions

Here are some of the most common documents and transactions that are supported through EDI automation.

Five Top EDI Documents to Automate

When you automate your most-used EDI documents, it can significantly cut down keystrokes and speed up processes.

EDI Glossary

Terminology including retail definitions, order management models, supply chain roles, software and distribution channels.

EDI for Suppliers & Vendors

Discover how leading vendor and supplier businesses are serving their customers better with EDI solutions from SPS Commerce.