Five ways to streamline order fulfillment for retailers

Are you a retailer who wants to streamline and simplify your order fulfillment channels? Do you want to assess your different channels to eliminate bottlenecks and sticking points? By using automation, electronic data interchange (EDI), and data analytics, you can find new improvements and even new fulfillment channels to please your customers.

But streamlining is more than just dropping one or two order fulfillment channels and trying to make everyone adopt a one-size-fits-all approach. Rather, it’s about analyzing which methods your customers use most, and seeing if there’s a way to remove any bottlenecks and unstick any sticking points that cause problems. It may even be a matter of adding another fulfillment channel — whatever it takes to keep your customers happy and coming back again and again.

Here are five ways retailers can streamline and optimize their order fulfillment channels:

1. To define your goal, assess and analyze the order fulfillment models you already have— in-house shipping, drop shipping, outsourced 3PLs, buy online pick up in store (BOPIS or BOPUS), in-store fulfillment (shipping from retail locations), and third-party marketplaces. Which ones are seeing the most significant sales from? What are the damaged shipment rates? Are you having any out-of-stock problems? How long does it take to fulfill and ship an order? These are your benchmarks. Your goal is to improve upon them.

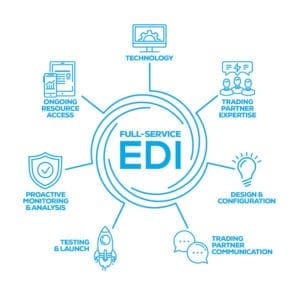

2. The next step is to integrate your systems and re-assess your processes. Not just your shipping processes, but your actual order fulfillment process. This integration can easily be done with an EDI solution. EDI systems can integrate with different software systems — ordering and eCommerce, inventory management, warehouse management, and accounting — and simplify your order processing.

Once you’ve integrated all your systems, and they’re all reading the same data, go back and re-assess all your order fulfillment models and see if you’re getting the same results. Ask the same questions from step one and see where things have improved or where you still might have problems. Focus on finding and improving on any new bottlenecks and sticking points you might have. With EDI in place, you should be able to eliminate many manual processes along the ordering process, so it’s necessary to know what changes have occurred in result of that.

3. The next step is to automate your processes, especially inventory communications. Don’t ever run out of a product again by setting up automatic inventory inquiries. These can come in the form of alerts that let you know when you reach a certain inventory threshold of your products, such as 10% of a particular product, or when you are nearing the end of a typical sales cycle. You can also set your inventory system to reorder specific products automatically when they reach a predetermined level.

You can also combine all the sales information from all of your fulfillment channels, so you don’t oversell or overcommit your products. Some companies will reserve a portion of their inventory for in-store sales and some for eCommerce. By streamlining your order fulfillment processes and integrating your systems, you can use EDI to keep track of your total inventory all in one place.

4. Next, align your different processes to reduce friction, especially beyond the ordering-and-fulfillment processes. For example, look carefully at how you package your orders for transportation. Are you using the smallest box possible, or do you have the right size boxes to pack the maximum number of items? Can you reduce the number of box sizes you need, or do you have a couple of dozen different box sizes just to accommodate the different products you send? Is it possible to reduce the number of box sizes by making a few adjustments to how you package your products?

Next, look at your returns. How can you reduce the friction here? In some cases, it may be appointing a singular returns location, such as a returns processing center, to manage all returned shipments. Or it may be allowing your eCommerce customers to bring their returns to your retail locations. While you don’t want to lose money on returns by having an inefficient process, you also don’t want to lose lifelong customers just because you were more concerned about having a returns process that was easy for you, but not your customers. Find out what your customers want in a returns policy and figure out how to give it to them.

5. Finally, be sure to continuously re-evaluate and reassess to see how your fulfillment processes can be improved. Make those changes and then measure again. Monitor your daily sales and returns numbers, look for complaints on returns, and measure order fulfillment times. Are things improving or at least not getting worse?

Compare your stats to industry expectations. If you know the industry benchmark is two-day delivery, are you meeting that? Or maybe your organization is small enough that you can’t offer those numbers. So, what are your best numbers? Are you improving them? If you’re meeting your benchmark and your customers are happy, then see if you can identify operational and cost efficiencies. But if everything is running on all cylinders, there’s no need to tinker too much. Now, it’s your job to make sure you can repeat that excellence every day, especially as you grow and add new products, stores, or fulfillment channels.

To learn more about how you can streamline your order fulfillment channels and make your customers happy. You can ask to speak to one of our fulfillment experts and receive a free demonstration of how our different solutions can help.

Find the correct EDI solution for your business.

Get more insights on full-service EDI by downloading our white paper.

READ OUR WHITE PAPER- Three common challenges 3PLs face and how to solve them - September 18, 2023

- Create retail branded packing slips for drop shipping - January 4, 2023

- A Simple Guide to Understanding the GS1-128 Barcode Label - July 7, 2021

RELATED POSTS

All-in-one: wholesale, marketplace, a...

Test new products online before stock...

How to Create a Positive Customer Exp...