5 ways technology drives down costs in retail, supply chain

People often like to complain about how technology has made our lives busier instead of easier, and with good reason. It has gotten easier to create more information, but that means we’ve got more to read. It has gotten easier to communicate with other people, but now more people want to communicate with us. And we’re able to do more things throughout the day, which naturally means we have to go to more meetings and we try to fit more and more into each day.

But technology really has made things easier and more efficient in the retail supply chain, and that has driven down costs and the prices we pay as consumers. Here are five ways technology — cloud-based software, automation, machine learning, and artificial intelligence — has found new efficiencies in the retail supply chain.

1. Data analytics help you make better decisions and insights

Very often, point of sales analytics paint an incomplete picture of a retail chain’s sales performance. They might get an overall trend of how a particular supplier is performing, or which products are meeting sales goals. But what about drilling down to the individual store level? What about spotting that one store that’s selling a higher-than-expected amount of product, or the store that hasn’t moved a single unit?

Looking more deeply at your analytics and identifying patterns quickly can help you discover problems, opportunities and successes that you may not see with your current analytics solutions. Sharing your point-of-sale data with your suppliers can get some extra pairs of eyes on your sales data and find those interesting trends that will drive sales and profit for both the retailer and the supplier.

Our Analytics solution can help you better understand your business performance and how to quickly make decisions based on early trends.

2. Drop ship-capable vendors can reduce inventory overhead

As more retailers join the e-commerce marketplace, they’re running into problems trying to not only fill up the Endless Aisle, they’re having problems figuring out where to keep everything or hiring people to ship it all for them.

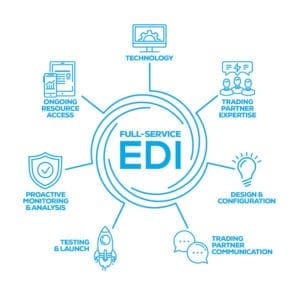

Some retailers are asking vendors to handle the drop shipping of orders on their behalf. This keeps the retailers from finding new warehouse and storage space, hiring new staff, or manage the inventory. Electronic data interchange (EDI) technology integrated with all of the necessary internal systems can assist with streamlining the order management processes required to accommodate more complex fulfillment models such as drop shipping programs. EDI ensures that the e-commerce order goes from the website, through the retailer’s system and directly to the drop ship-capable supplier.

3. Ship from store or ship from nearest distribution center

Retailers who want to expand their capabilities beyond drop ship-capable vendors can choose to manage their own shipping. Some stores have begun using their brick-and-mortar stores to ship e-commerce orders. For business looking to more effectively manage their shipping to expand their assortment and reach, ship from store is a possibility. This lets them pull from in-store inventory, which can improve their overall inventory turnover. It can even help individual stores move certain inventory items that may be lagging otherwise. (This is where having a good POS analytics program can also make a big difference.)

When it comes down to it, any place can be a fulfillment center, though there is some complexity because in-store product availability can then impact online shoppers and in-store shoppers. Thinking through the logic of the system, advanced visibility to where future shipments are at can allow you to fulfill that one item because you know later that day, a shipment of more are coming into the store. Ship from store maximizes the square footage of what you have now, you just have to make the investment in the staff and inventory.

Other retail brands have created several regional distribution centers to manage their e-commerce fulfillment. They’re able to ship products out faster by planting a small handful of regional centers around some of the areas where they get their biggest sales. This allows them to offer two-day shipping and same-day shipping for a low price or even free. Both the distribution center and ship from store order fulfillment model allows retailers to maximize inventory and speed to hit one day, two day, three day shipping.

SPS has experience assisting retailers and distributors on both business models, and our integrated order management and fulfillment solutions help companies find new ways of reducing their shipping costs and delivery times.

4. Inventory visibility avoids out-of-stock issues online

Suppliers can also benefit from sharing their inventory availability with their retailers. For example, an online retailer gets regular real-time updates on a supplier’s inventory counts, which the retailer can then share online. Customers visiting the website will see real-time availability of a particular product, which can help them make faster buying decisions. And retailers can even automatically remove the items from their websites to avoid any out-of-stock issues that might arise.

Inventory visibility throughout the retail supply chain offers a variety of benefits for keeping customers happy. It assists with knowing when and how much to re-order, and enables automatic re-order so you never run out of stock. It can help with understanding when to take items off the website because stock is too low, and when to put it back on the website when stock is replenished, preventing customers from trying to order something you don’t have, just to be met with a “We’re Sorry” message after they’ve paid.

This is where EDI and inventory visibility can make a big difference in a retailer’s performance, enabling more “perfect order” completions.

5. EDI can reduce errors and manual data entry

Speaking of automatic reordering, not only can an automatic reorder help you avoid running out of a particular item, EDI can speed up the process even more. For example, when a buyer places a purchase order, that can automatically trigger a purchase order acknowledgement from the supplier, and enter the order into the system. This is a big improvement over faxing an order and having it manually entered into the supplier’s ERP system.

Further, this order will travel all the way through the system to the warehouse, where picked-and-packed orders are compared to the original PO, errors are quickly identified, and the shipping list is automatically created and returned to the retailer as an Advanced Shipping Notification. After the order has been received, the invoice can be automatically generated and compared in a three-way match with the other documentation. Three-way matching and other similar automated reconciliation processes can assist with ensuring correct and timely payments to take advantage of on-time discounts.

Imagine going through this entire process by hand — manually placing an order, entering it into the system, creating the packing list, and then three-way matching all the documentation. It was a big time waster for both the supplier and the retailer, but EDI has turned a labor intensive process that’s wrought with errors into something that can be handled by one person in each company into an automated process to save costs and time.

SPS Commerce has worked hard to create the kind of technology to help retailers and grocers, suppliers, and third-party logistics providers find efficiencies within their segment of the retail supply chain. This helps them avoid running out of items, get items to more customers faster, find new trading partners, and even analyze their performance and identify problems before they become too large to manage. For more information on any of these solutions, or to speak to one of our experts.

Find the correct EDI solution for your business.

Get more insights on full-service EDI by downloading our white paper.

READ OUR WHITE PAPER- Save big money with order automation - January 17, 2025

- A collaborative approach to supplier performance management - November 7, 2024

- How to nail your next buyer meeting: A supplier’s guide - August 29, 2024

RELATED POSTS

Tackling omnichannel order management...

Three common challenges 3PLs face and...

Create retail branded packing slips f...