What is a 2D barcode and how does it work?

Whether you’re a retailer, distributor, grocer or supplier, you’re probably familiar with traditional barcodes. You’ve likely worked with UPC codes on consumer products and UCC-128 labels on shipping cartons and pallets. These 1D (one-dimensional) barcodes have served commerce well, encoding essential information like product identifiers, quantities and shipping details.

But a significant shift is changing how companies track and identify products throughout the supply chain. 2D barcodes are emerging as the next standard, and they pack dramatically more information into a compact square format. While a UCC-128 shipping label might hold 48 characters of data, a 2D barcode can store thousands of characters, including serial numbers, batch codes, expiration dates and much more.

Major retailers are preparing for 2D barcode adoption, and new industry standards will require point-of-sale systems to accept 2D barcodes globally by the end of 2027. This means businesses across the supply chain must understand how 2D barcodes work and prepare their operations for the transition.

Why 2D barcodes are replacing traditional barcodes

The push toward 2D barcodes comes directly from consumer demand. According to recent research by industry standards body GS1, 77% of shoppers say product information is important when making purchases, and 62% are willing to spend more on products that offer detailed information. Additionally, 79% are more likely to purchase products with scannable codes that provide extra product details via smartphone.

The information consumers want most includes nutrition facts, materials and ingredients, safety information, country of origin, allergen warnings and recall alerts—far more than a traditional 1D barcode can hold.

Consumer pressure has accelerated industry adoption. The transition is already underway, with 2D barcode technology being tested in 48 countries that represent 88% of the world’s GDP. Major retailers are preparing for 2D barcode adoption, and new industry standards will require point-of-sale systems to accept 2D barcodes globally by 2027 under the GS1 Sunrise 2027 initiative.

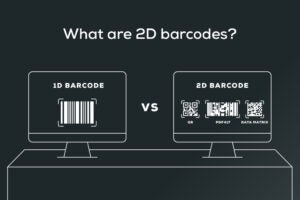

What are 2D barcodes?

A 2D barcode stores information in two dimensions—both horizontally and vertically.

In contrast, a 1D barcode stores information horizontally.

The most common types of 2D barcodes include:

QR codes are square, pixelated codes you scan with your smartphone. Originally developed in Japan for tracking automotive parts, they’re now everywhere from restaurant menus to marketing materials.

Data matrix codes are smaller, more compact squares often used in manufacturing and healthcare. You might see these on prescription bottles or electronic components.

PDF417 codes are rectangular barcodes that look like tiny bricks stacked on top of each other. These are commonly used on driver’s licenses and shipping labels.

So, is a QR code a 2D barcode? Absolutely! QR codes are the most recognizable type, but they’re just one variety of advanced barcode technology.

How do 2D barcodes work?

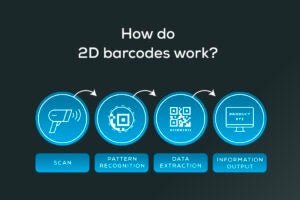

2D barcodes work by encoding information in patterns of dark and light squares, rectangles or dots arranged in a grid. Instead of reading information linearly from left to right like traditional barcodes, scanners read 2D codes in multiple directions.

Here’s what happens when you scan a 2D barcode:

- Pattern recognition: The scanner’s camera or laser identifies the finder patterns (those larger squares in the corners of QR codes, for example) to understand the code’s orientation and size.

- Data extraction: The scanner reads the arrangement of dark and light modules across the entire code, converting the visual pattern into digital information.

- Error correction: Most 2D barcodes include built-in error correction, meaning they can still be read even if part of the code is damaged or obscured.

- Information output: The scanner processes the data and presents it in a readable format, whether that’s a website URL, product details or other encoded information.

How much data can a 2D barcode hold? It varies by type:

- QR codes can store up to 4,296 alphanumeric characters.

- Data Matrix codes can hold up to 2,335 alphanumeric characters.

- PDF417 codes can store up to 1,850 alphanumeric characters.

The massive capacity difference explains why 2D barcodes can include detailed information like batch numbers, expiration dates, serial numbers and even complete product descriptions.

Creating and scanning 2D barcodes

How to create 2D barcodes

Businesses have several options for generating 2D barcodes, depending on their volume needs and technical requirements.

For small-scale needs, online generators offer a simple solution. Search for “QR code generator” or “2D barcode generator,” enter your information (text, URL, contact details) and download the resulting image.

For office integration, creating 2D barcodes in Excel is possible through add-ins or formulas that generate QR codes.

For enterprise operations, businesses choose between dedicated barcode software for bulk creation or integrated solutions that connect with existing supply chain systems. Many companies prefer platforms that generate compliant barcodes and integrate data with trading partners.

How to scan 2D barcodes

Many small businesses begin by using mobile phones to scan barcodes. On an iPhone, open the Camera app and point it at the barcode. A notification will appear at the top of the screen. Tap it to view the information. Most Android phones offer a similar experience.

As a business grows, receiving processes often become more complex. At that point, companies typically move to tablets or dedicated scanners. These devices may be handheld or mounted and are built to handle higher volumes. They also connect directly to ERP or WMS systems, making it easier to manage inventory at scale.

Most modern scanners can read both 1D and 2D barcodes. If you’re using older equipment, look for “2D imaging” or “area imaging” capabilities. Laser-only scanners may not support 2D codes.

Scanner compatibility and technical questions

One of the most common questions businesses ask is: can a 2D barcode scanner read 1D barcodes? The short answer is yes, almost always.

Modern 2D scanners use imaging technology (essentially tiny cameras) that can capture and decode both 1D and 2D barcodes. This means businesses can upgrade to 2D scanning equipment without losing the ability to read traditional UPC codes and other 1D formats.

However, the reverse isn’t true. Traditional 1D laser scanners can’t read 2D barcodes because they only scan in one direction. If you’re still using older laser scanning equipment, you’ll need to upgrade to 2D imaging scanners to read the new barcode formats.

When evaluating scanner upgrades, consider:

- Imaging vs. laser technology: 2D scanners use cameras, 1D scanners use lasers.

- Reading distance and angle: 2D scanners are generally more flexible about positioning.

- Durability requirements: Industrial environments may need ruggedized 2D scanners.

Benefits of 2D barcode technology

2D barcodes provide several key benefits:

- Enhanced traceability: Batch numbers and expiration dates encoded in the barcode improve recall response and inventory management.

- Supply chain transparency: 2D barcodes track detailed product information from manufacturer to consumer.

- Consumer engagement: Shoppers scan products with their phones to access detailed information, reviews, recipes or promotional content from the same checkout barcode.

- Operational efficiency: A single scan captures pricing, promotional details and inventory data, reducing checkout errors and speeding up transactions.

- Regulatory compliance: Pharmaceutical and food industries increasingly require detailed product tracking that 1D barcodes can’t support.

- Better product authentication: 2D barcodes combat counterfeiting and build brand trust through verified information.

The transition to 2D barcodes won’t happen overnight. Businesses need to upgrade point-of-sale systems, update packaging processes and get their supply chain partners ready. But the benefits, from improved food safety to better customer experiences, are expected to drive rapid adoption across retail chains.

Common applications and use cases

2D barcodes are already transforming operations across industries:

Retail and consumer goods: Companies authenticate products, share ingredient information and run promotional campaigns that connect physical products to digital experiences. 2D barcodes on shipping labels consolidate shipment details, item information and receiving instructions into a single scan, providing complete supply chain visibility from warehouse to store.

Healthcare and pharmaceuticals: Medication tracking creates full traceability from manufacturer to bedside, reducing medication errors and meeting regulatory compliance requirements. Healthcare providers can track batch numbers and expiration dates throughout the entire supply chain.

Manufacturing and automotive: Quality control systems track parts throughout complex supply chains and rapidly identify defective components. Production data, batch numbers and quality control information travel with products from manufacturing through distribution, creating complete visibility into the production process.

Food and beverage: Lot tracking systems enable rapid response to contamination issues and provide consumers with detailed sourcing information. Companies can trace products from farm to table, improving food safety and meeting transparency demands.

Electronics and technology: Manufacturers embed serial number tracking, warranty information and anti-counterfeiting measures directly into product labeling. This creates visibility into product authenticity and ownership throughout the device lifecycle.

The future of 2D barcodes

2D barcodes are more than just a technical upgrade. They open the door to entirely new ways for businesses and consumers to interact with products. As scanning technology advances, expect to see:

- Dynamic content: Barcodes that link to real-time information like pricing, availability, or promotional offers

- Personalized experiences: Product scans that deliver different messages or offers based on the user, time, or location

- IoT integration: Barcodes that connect physical products to smart systems for reordering, maintenance, or usage tracking

- Enhanced security: Built-in authentication features that make counterfeiting much more difficult

- Sustainability tracking: Lifecycle data that helps consumers make environmentally responsible choices

2D barcode technology is already in use, and early adopters are seeing strong returns. As momentum builds, businesses that prepare now will be better positioned to take full advantage of what’s ahead.

Getting started with 2D barcodes

The simplest approach involves starting small by creating a 2D barcode for a business website or contact information to test customer response. The barrier to entry is lower than most expect.

Begin by examining current barcode scanning equipment and identifying where 2D barcodes could add value. Try testing 2D barcodes with key processes before expanding across your company.

Organizations worldwide are already implementing 2D barcode technology across their supply chains. Understanding how they work and planning for implementation now positions operations for the transition to this new standard in B2B commerce and product identification.

Scanning for what’s next

2D barcodes give you the detailed data you need: batch numbers for recalls, expiration dates for compliance and serial numbers for authentication. But having this data only helps if you can act on it across all your sales channels.

Ready to put your data to work? Omnichannel fulfillment turns improved data into seamless experiences online, in-store and everywhere customers shop.

- What is a 2D barcode and how does it work? - June 20, 2025

- How suppliers can align to retailers’ spring and summer seasonal demands - February 21, 2025

- RFID: Everything you need to know - October 28, 2024

RELATED POSTS

Predictability pays off: why retail l...

Overlooked Strategies for Managing Vo...

How to achieve order automation – e...