The bullwhip effect in supply chain management: definition, causes and examples

The bullwhip effect can create challenges for even the most well-managed supply chain. Factors like sudden demand shifts, poor forecasting or external shocks such as tariffs can trigger costly ripple effects. Understanding how the bullwhip effect occurs is essential to preventing future disruption.

What is the bullwhip effect in supply chain management?

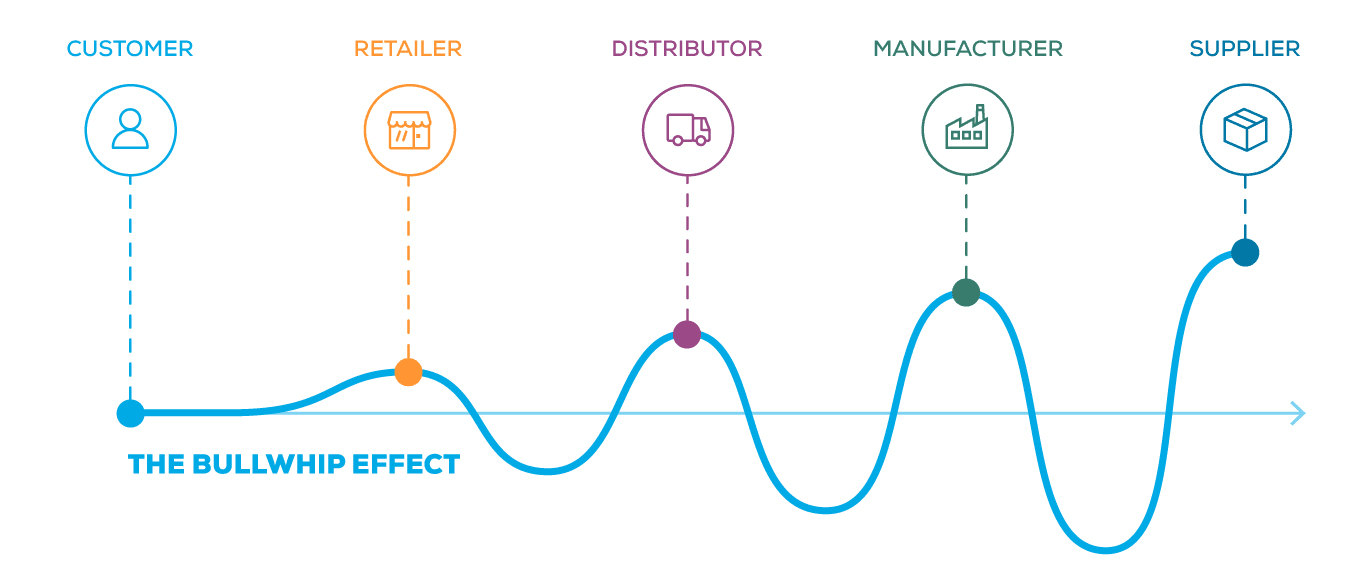

The bullwhip effect, also known as the Forrester effect, is a phenomenon that occurs within a supply chain. It describes how small fluctuations in retail demand can cause ripples up the supply chain that get progressively larger and more devastating.

It takes its name from the process of cracking a whip, where a small snap of the wrist creates a ripple effect that generates a much larger movement in the whip.

Imagine that a retailer stocks 10,000 rolls of toilet paper, and, on average, sells 2,000 rolls a day. Instead of ordering 5,000 rolls a day and ending up with a huge surplus, the retailer orders exactly the amount needed from the distributor to keep up with demand.

Something (like the recent pandemic) drives up the demand for toilet paper by a large margin. One-day sales reach 7,000 rolls, and the retailer assumes that customers will start buying more. In response, they order twice the amount of stock to keep up with this demand.

In turn, the distributor starts to order double the amount of stock from the toilet paper supplier, which drastically increases its production to capitalize on the demand. After a short period, demand returns to a typical level, leading to wasted stock and spending throughout the supply chain.

This is the problem the bullwhip effect presents: an artificial increase in demand that vastly exceeds the true stock requirements, often leading to waste.

How to spot the bullwhip effect

While the bullwhip effect may not be immediately obvious, there are many ways to identify it during its early stages, which will provide the early warning needed to counter the effects:

Sudden demand spikes:

If demand for products suddenly spikes by a small amount, it may be an early sign of the bullwhip effect. This can be investigated in a retail analytics platform, comparing current demand against historic data to see if this may be a seasonal trend or if any similar patterns have occurred previously. This additional context can provide information on how to deal with the sudden spike without allowing a bullwhip effect to occur.

Demand overcompensation:

When responding to high customer demand, it is natural to order extra stock to account for potential demand spikes. However, when this surplus continues over time, the excess inventory can disrupt the entire supply chain.

Inaccurate inventories:

When responding to high customer demand, it is natural to order extra stock to account for potential demand spikes. However, when this surplus continues over time, the excess inventory can disrupt the entire supply chain.

Causes of the bullwhip effect

The bullwhip effect can be caused by a number of seemingly small trends or behaviors that build up to create serious challenges throughout the supply chain, including:

Incorrect demand forecasting:

One of the main causes of the bullwhip effect is inaccurate demand forecasting. When a company can’t understand future demand, it’s impossible to plan for the future.

Increased customer demand:

Various factors can affect customer demand, from world events like pandemics, to word of mouth and social media creating a new craze for a particular product. When demand suddenly or unexpectedly increases, a supply chain can experience the bullwhip effect.

Too many discounts/promotions:

Sometimes, when a retailer offers too many discounts and promotions, it can lead to demand that doesn’t accurately reflect available stock. When this happens, retailers might call for additional stock to meet presumed demand only to find that demand has faded.

Poor communication:

If supply chain partners do not communicate effectively and share data, accurate demand forecasts deteriorate during discussions. This could result in one stakeholder having a very different idea of how much they need to produce than another, causing a bullwhip effect.

Not all disruptions start within the supply chain. Some come from outside forces that are harder to predict or control.

External factors that amplify the bullwhip effect

Some supply chain disruptions stem from external factors. For example, tariffs, trade restrictions and geopolitical tensions can create uncertainty that magnifies the bullwhip effect.

Tariffs and trade policy shifts can cause businesses to place unusually large or rushed orders in anticipation of higher costs. For example, a retailer may order large quantities of goods ahead of a tariff deadline, triggering upstream panic and overproduction. When the policy stabilizes or demand doesn’t hold, the result is overstock, waste and strained supplier relationships. In response to higher costs, some businesses raise prices, which may then be passed along to consumers. Others absorb the costs, straining their margins and creating potential instability across the supply chain.

To stay agile, businesses need flexible sourcing strategies, transparent supplier communication and access to timely data. This mitigates the impact of external shocks like tariffs and prevents unnecessary ripple effects across the supply chain.

How does the bullwhip affect the supply chain?

When a supply chain is caught in the bullwhip effect, one of the biggest impacts it sees is overcompensation in inventory production. Suppliers ship out more raw materials, while manufacturers produce more products and distributors send out more stock than necessary to retailers.

Not only does this create a surplus that may take up space in warehouses and distribution centers, but it also wastes materials that could be better used to produce other products, while increasing holding costs, energy costs and unused stock.

Below is a short example of how the bullwhip effect affects each stakeholder within a supply chain:

Customers

Customer demands spike because of increased discounts, promotions or social media trends. Customers may initially run into out-of-stocks of the in-demand product.

Retailers

Retailers increase orders and demand forecasts, but are left with unsold products, increasing waste and reducing profits.

Distributors

Distributors overestimate the demand across customers and overcompensate with excess stock. They may also be left with unsold inventory.

Manufacturers

Manufacturers overproduce stock based on the increased demand for the product. When the demand cools, they have an excess of product and lose profits.

What does a bullwhip effect indicate?

When the bullwhip effect appears in a supply chain, it could indicate a host of compounding problems, including:

Communication problems

Trading partners may struggle to communicate effectively, requiring new policies to improve communication.

Problems in the supply chain

The bullwhip effect might indicate a problem within a stakeholder organization in the supply chain, including poor management of resources or personnel.

Poor demand forecasting

The bullwhip effect could also indicate poor or inaccurate demand forecasting. Initiatives would need to be put in place to improve data gathering and forecast accuracy.

How to prevent the bullwhip effect

The bullwhip effect is preventable with the right data and communication channels.

Below are several key strategies to prevent the emergence of the bullwhip effect:

- Establish better stakeholder collaboration

One of the best ways to minimize the bullwhip effect is to improve communication, speed and efficiency throughout the order cycle. Each stakeholder needs to adopt best practices for regular and clear communication throughout the order cycle to help avoid knee-jerk reactions when small patterns or behaviors emerge. This way, all partners align on stocking decisions and avoid issues that can affect the broader supply chain. - Use technology to optimize processes

Another way to remove human error and gain accurate data for demand forecasts is to automate processes through retail technology. Automation (specifically machine learning) can be used for processes such as inventory planning, inventory management, raw material planning and much more. - Conduct frequent inventory evaluation

Frequent inventory evaluation is another way stakeholders can understand exactly how much stock is sitting unused, so they can avoid increased holding costs and waste of raw materials. This regular monitoring also mitigates the bullwhip effect by keeping an up-to-date log of consumer demand that can be shared among all stakeholders in the supply chain. - Reduce delays

A decrease in delivery time can play a significant role in reducing the bullwhip effect. The longer it takes for inventory to move through the supply chain, the greater the risk of retailers making reactive stocking decisions, which can then spiral to create overstocking, waste and further backlogs and delays. - Reduce order sizes and stabilize pricing

Retailers can also reduce the size of their orders to better respond to a volatile market with greater speed and accuracy. Similarly, avoiding erratic discounting in favor of more stable pricing structures can help improve the predictability of demand.

Frequently Asked Questions (FAQs)

Q: Can tariffs cause the bullwhip effect?

A: Trade policies such as tariffs can intensify the bullwhip effect. When businesses expect price hikes, they may over-order to get ahead of cost increases. Inventory stockpiling can distort demand signals across the supply chain, leading to misaligned production, waste and higher costs.

Q: Is the Forrester effect the same as the bullwhip effect?

A: Yes, the Forrester effect is simply another term for the bullwhip effect, which is the unexpected or unpredicted spike in demand that travels up the supply chain from the consumer and ends at the raw materials provider.

Q: What are the three impacts of the bullwhip effect?

A: There are three major impacts the bullwhip effect has on businesses. One is a breakdown of communication, making it harder to effectively warn other stakeholders in the supply chain. Next is inaccuracy in data acquisition. Most stakeholders will be operating on out-of-date or incorrect data. The third impact is a surprise shift in demand that can make predicting the next forecast a near-impossible task.

Q: What are the four effects of the bullwhip effect on the supply chain?

A: There are four main ways a supply chain can be affected by the bullwhip effect. The first is excessive inventory investment that carves away a chunk of business profits. The other three are misguided capacity plans, ineffective transportation and ineffectual or missed production schedules.

Q: How does the bullwhip affect manufacturing?

A: When the bullwhip effect has traveled far enough up the supply chain to reach the manufacturing stakeholders, it can often result in a sudden spike in goods being manufactured for a consumer base that doesn’t exist. This means materials are wasted producing inaccurate quantities of stock for inconsistent and fluctuating inventories.

Simplify your supply chain

SPS Commerce empowers retailers, grocers, distributors and suppliers to simplify and automate data exchange, so they can prevent supply chain disruptions and enhance customer experience.

Visit our website or connect with a supply chain expert to learn how we can help you overcome the bullwhip effect and other supply chain challenges.